The Converge Electronic TechLog is customisable to your specifications, giving your pilots and engineers familiar layouts and fields based your existing paper techlog, or on other applications you use. It can be as simple as couple of pages of data to fill out, or can be extensive and incorporate other modules such as Damage Recording, or Document Management. And of course with everything being remotely managed, you have the ability to modify your configuration across your entire fleet in a precise, controlled manner however, and whenever, you wish.

With the use of the ETL, we have substantial improvements in quality and efficiency. Through the digitalisation of the data we secure the transfer of error free readings on the current overall real time status of the aircraft, including all maintenance and crew activity. After only a short period from the start date using the ETL live, not a single employee wants to go back to the paper process.

A lot of the benefits arising from the Electronic Techlog are associated with it's ability to send and receive data (i.e. to be connected to the CONVERGE servers), indeed our solution is designed to be flexible and will use any available type of connection. Also, the hardware solutions we recommend have SIM card slots to ensure they maximise the chance data connectivity.

However, the CONVERGE Electronic Techlog does not require a connection to perform as the techlog. This is a subtle, but crucial, point to understand. Your techlog solution must work whether the location you are in has a mobile phone/WIFI signal or not. If the proposed solution just stops working because there is no data connection - then it is no solution at all.

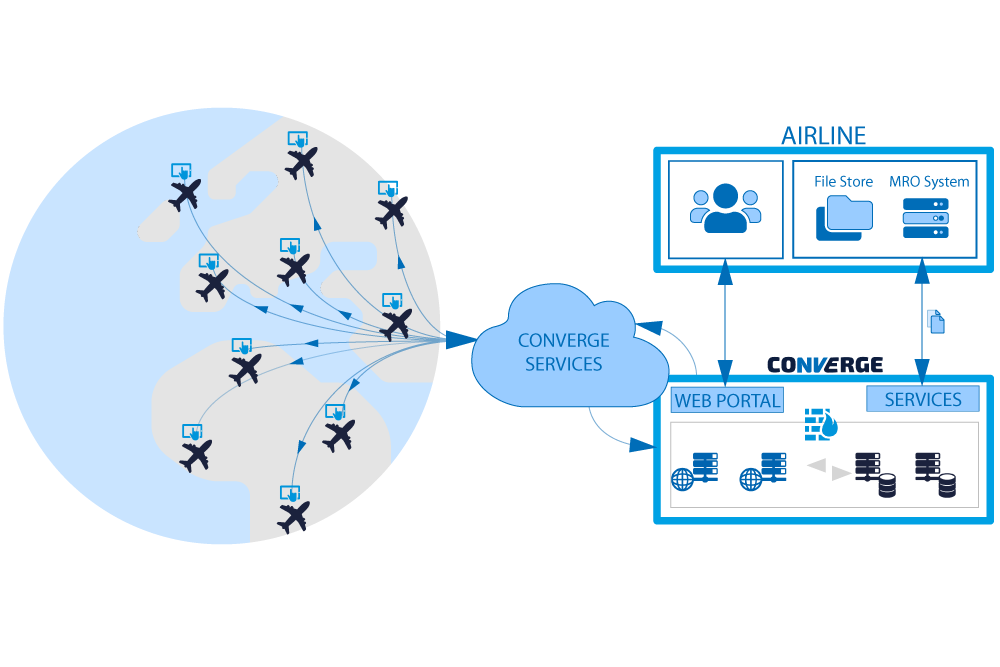

The diagram above shows a very simple overview of how our solution works.

- On AircraftEach aircraft has at least one tablet device assigned to it. There are various options such as the type of tablet (Windows, iOS, Android) and also whether you have fail-over devices. Regardless of these decisions we do recommend that the device is assigned to an aircraft rather than using "personal issue" devices. The technical log has always stayed with the aircraft and we believe that is the correct approach when changing to an electronic version. Having a device assigned to an aircraft reduces the risk of incorrect logs being used and also ensures that line engineers have access to the correct state of the aircraft. We also recommend having a mobile printer so that a sector record can easily be left on the ground in locations where there is no data connectivity.

- On GroundThe CONVERGE website provides access to the data being sent from the fleet of techlogs. At the core of the service is the provision of the sector data in various formats (e.g. PDF, XML, JSON etc) for archiving and for automatic data feeds into various systems. The website not only allows access to all data, analysis and dashboards but also provides user with functionality to control and configure the system. This includes user and role management; managing the correction process; updating aircraft configuration etc. Depending on the modules included in the CONVERGE ETL this is also where documents are managed, damage is controlled and overnight line maintenance activities can be planned and monitored.

- Data InterfacesData interfaces were mentioned above, particularly the feed to the Maintenance system. However we see the ability to collate, transform and forward data in whatever format you require to be a key benefit of our solution. We have active automated feeds to multiple systems for multiple reasons and we are happy to support you in making life a little simpler in automating what we can. We can also accept data feeds from multiple systems. The purpose can be to synchronise configurations or work requested with the Electronic Techlog, but we also assist in analysis and reporting of unrelated data.