The technical log is a key document in the aircraft operation, controlled by the local aviation, authority and provides crucial oversight

There have been technical logs recorded since just about the first flights. They record the status of the aircraft prior to each flight as well as the line maintenance activities. In fact, one of the reasons we chose to invest in providing an electronic techlog (ETL) was that there were no good tools supporting line maintenance.

This seemed ridiculous given the importance of those activities in the daily airline operation. The problem is that the technical log is document that is completed by two sets of users and it's primary benefits are felt by others in the airline. The pilots and line engineers complete it but it is Maintenance Operation Control, Tech records and Engineering that get the most benefit.

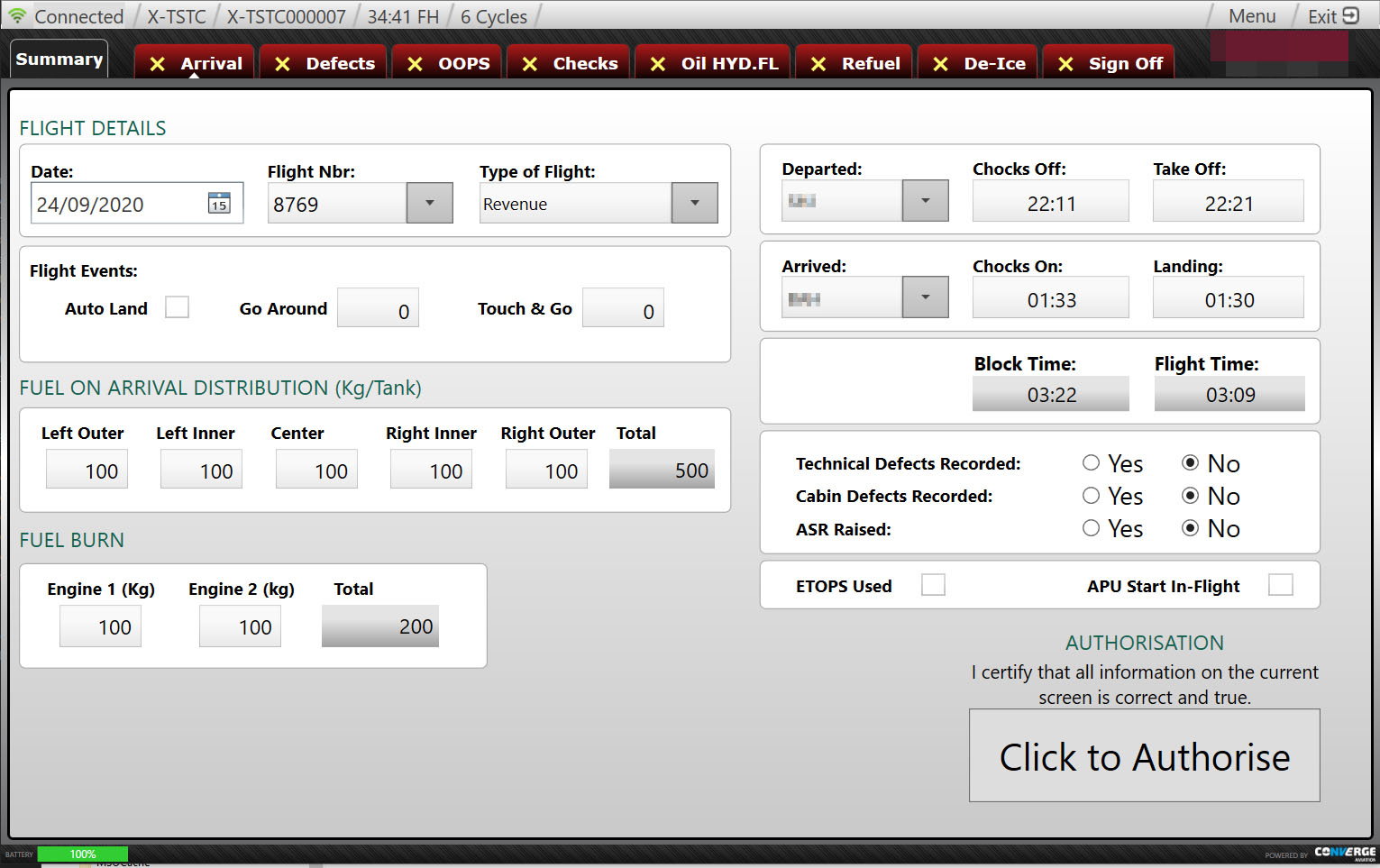

With that in mind we set about creating an "On Aircraft" solution that was easy to use but as helpful as it could be for the people actually using it as well as providing all the other benefits to the airline.